Unfavourable operating conditions? Detect, stop, save costs!

- Sep 21, 2022

- 2 min read

Updated: Nov 22, 2022

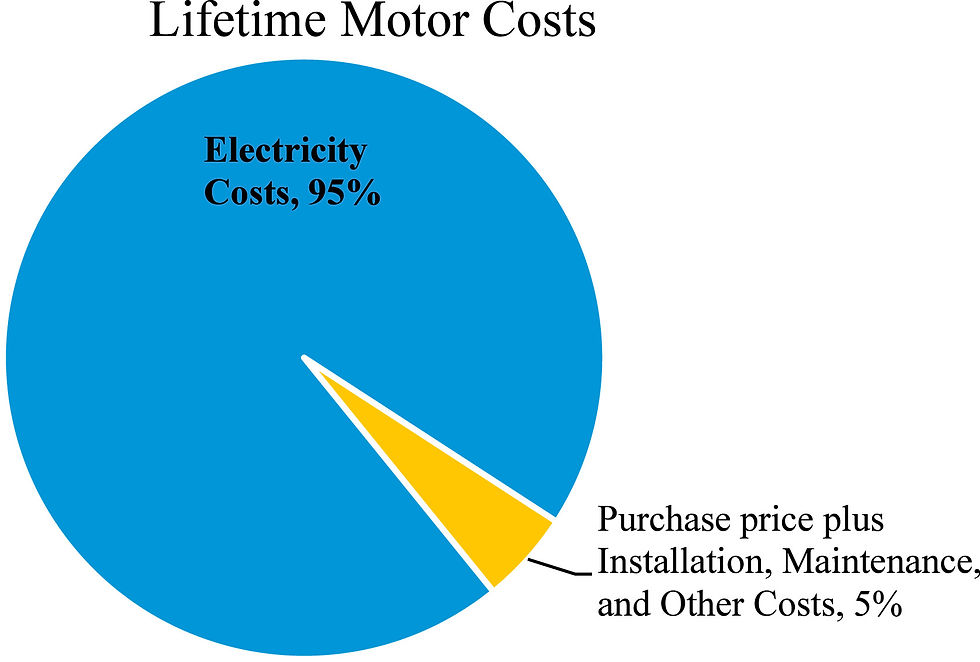

Machine drives and motors often cause the greatest energy consumption of a plant. Considering that, for example, 95 % of the life cycle costs of a motor alone are energy costs¹, this sounds like a call, even a necessity, to reduce these costs. One of the direct ways to save energy is to identify unfavourable operating conditions...

What drives up the energy consumption of a drive? The answer to this question is to recognise and stop such "unfavourable operating conditions". It subsequently helps to reduce energy costs. Unfavourable lubrication conditions, for example, are not exactly conducive: after all, poor lubrication creates friction. And friction in turn leads to more intensive energy consumption and thus to higher energy costs². And not only that: lubrication problems are often the cause of plant downtimes. 80 percent of premature rolling bearing failures alone can be attributed to this. If a bearing does not reach its intended service life, it is not only expensive because a replacement is needed. If we think further, it is also bad overall in terms of the CO₂ balance and environmental protection.

How to detect unfavourable lubrication conditions?

By means of ultrasound. Because: Friction generates ultrasonic frequencies that can be identified in an uncomplicated and reliable way. Whether the lubricant is too little, too old or simply wrong³ - the best technology to detect bad lubrication conditions is ultrasonic technology.

If the problem is subsequently corrected, friction can be minimised, energy is saved and the budget is spared, because the bearings last much longer. In the end, only the bearing manufacturer benefits from a bearing failure. For the user, there are only difficulties.

Important for the selection of the solution provider is therefore the question: Who has an interest in my bearing lasting as long as possible? Ultrasound technology is part of the problem solution.

¹ „The current state of the industrial energy assessment and its impacts on the manufacturing industry”, McKenna Patterson, Prashant Singh, HeejinCho, 2022, Energy Reports, Pages 7297-7311

² “Global energy consumption due to friction and wear in the mining industry”, Holmberg, Kenneth; Kivikytö-Reponen, Päivi; Härkisaari, Pirita; Valtonen, Kati; Erdemir, Ali (2017-11-01)

³ “Common Causes of Bearing Failure and How to Avoid Them”, 2021, Georgy Armstrogg

Author: DI. Mag. Markus Loinig

Email: markus@senzoro.com